Material Handling

Improve Workflow by Reducing Time and Movement

Material Handling refers to the movement, storage, protection, and control of materials and products. Whether hands-on lifting and moving, utilizing manually controlled devices, or operating automated material handling equipment, the safe and efficient movement of materials is usually required as part of every production worker's job.

The old adage, "Time is Money" was coined in 1748 by an American founder and great entrepreneurial businessman, Benjamin Franklin.

The old adage, "Time is Money" was coined in 1748 by an American founder and great entrepreneurial businessman, Benjamin Franklin.Back in 1748, the great American entrepreneurial businessman, Benjamin Franklin, coined the old maxim, "Time is money". Often repeated since then relating to all types of business, this adage holds true in every aspect of Material Handling. Both time and money are essential commodities. Making every moment as well as every movement count is efficiently.

When the goal of the right material

handling system for your company is achieved, manual labor is decreased, delays diminished, damage,

loss and waste are minimized, and the workflow efficiency increases. Efficient use of time and movement in the storage, control and

production of materials and products results reduced costs, and thus increased bottom-line profits are the results. Organization through optimal storage solutions and time-saving equipment increases efficiency and maximizes profitability.

It’s never too late to consider workplace improvements

or to explore new material handling solutions.

The time, attention, and effort put into developing an efficient and effective material handling strategy that works best for your company, certainly pays off in the end. Added benefits are greater proficiency in the staff, improvement in your customer service track record, and increased over all performance of the company.

"A clean and well-organized warehouse

communicates to

staff, clients, suppliers and visitors

that you are

on top of your business game!"

@ SampsonInd.com

No matter the setting, business owners, managers of warehouses, and every facilities director knows that maintaining a clean, orderly workplace can be one of the biggest struggles if not given proper attention. But a workplace that is implementing even simple organizational principles reaps many valuable benefits making the time, effort and expense required well worth it!

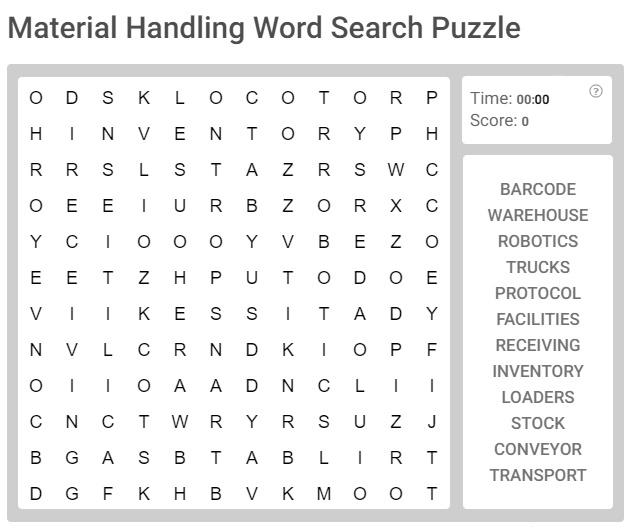

20 Great Reasons to Implement

Efficient Material Handling

- Streamlines workflow

- Increases space efficiency

- Increases productivity

- Reduces material damages

- Materials are easily accessible

- Maximize inventory management

- Minimizes unneeded inventory

- Increases organization of products

- Reduces production interruptions

- Enables streamlining operation

- Facilitates product control

- Improves overall handling costs

- Diminishes wasted time

- Minimizes delivery time

- Improves customer service

- Encourages employee morale

- Assures personnel safety

- Keeps warehouse tidy

- Simplifies warehouse logistics

- Communicates success

© SampsonInd.com

In industrial and commercial settings, proper attention and planning given to warehouse logistics enables material handling solutions that will increase efficiency. This can be a deciding factor between success or failure in workplace functionality. Optimal workflow is experienced when organization, order and safety are priority. Careful attention to the material handling system and workplace logistics directly increases

productivity and safety, and greatly reduces wasted time as well as damaged or

misplaced goods. The quality of customer service will be enhanced as well which will result in increase of profitability. Here are 20 great reasons to implement efficient material handling at your facility.

Are there any changes that you might be considering that would make a difference at your workplace?

What are some of your company’s successful material handling strategies?

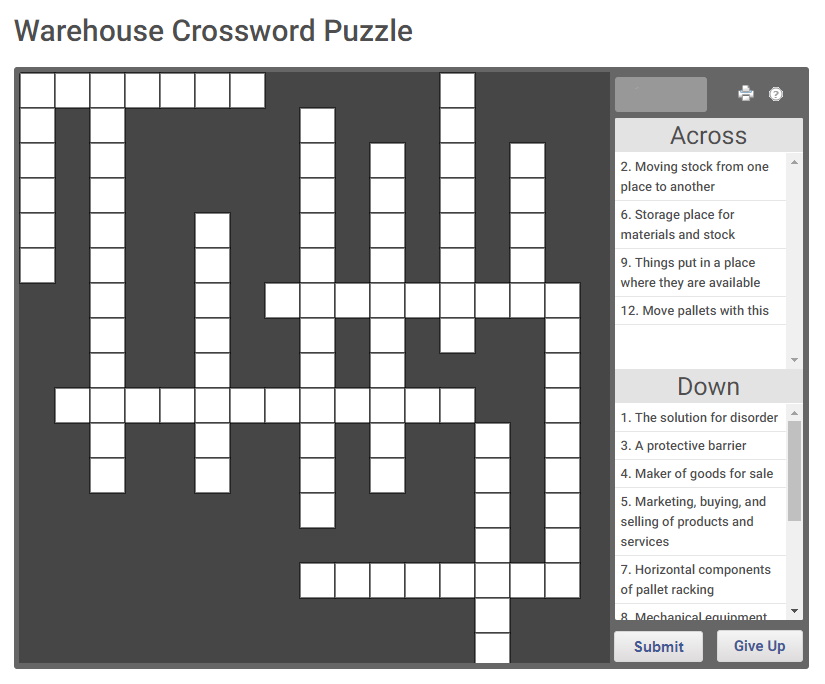

Industrial and Commercial

Material Handling: Go for Flow!

J Sainsbury's regional distribution center at Waltham Point is large, busy. Their pallet rack shelving is neatly organized and their material handling equipment is being implemented creating an efficient, seamless flow. Photo: Public Domain

J Sainsbury's regional distribution center at Waltham Point is large, busy. Their pallet rack shelving is neatly organized and their material handling equipment is being implemented creating an efficient, seamless flow. Photo: Public DomainBesides the added profitability of your company, your employees will appreciate the time and resources that you dedicate to making sure their working environment is safe, organized, clean, and efficient. This often results in employees who experience less stress and they often take more pride in their work. Knowing that their workplace operates in compliance with Health and Safety regulations in your area would be important to all who are employed there.

In the grand scheme of material handling, the importance of quality industrial pallet racking for your storage needs cannot be minimized. Whether you are looking to expand your warehouse storage, or improve the flow of your material handling, we are here to assist you. Are there any ways that your company can improve on the present material handling strategies?

Agriculture: A Huge Field of Applications!

In the wide field of Agriculture, industrial pallet racking is an ideal storage solution for Co-ops, machine shops, barns, sheds, and in any other type of Agricultural building.

Photo Credit: Wilson Farmers Co-op

In the wide field of Agriculture, industrial pallet racking is an ideal storage solution for Co-ops, machine shops, barns, sheds, and in any other type of Agricultural building.

Photo Credit: Wilson Farmers Co-opFar beyond the typical commercial and industrial settings that the words "material handling" usually bring to mind, lies the vast field of agriculture which is so necessary to our existence. Industrial pallet racking is an ideal storage solution for machine shops, barns, sheds, and in any other type of Agricultural building. As pictured above, Wilson Farmers Co-op in Lebanon, Tennessee, which has specialized in farm equipment and supplies for many years, utilizes warehouse pallet racking to shelve their feed, seed and other farm and rural commodities.

No matter the sector, in industry, commerce and agriculture, material handling has always been an integral part of most workplace activities. This has been true since ancient history when mankind was faced with the need to move material loads.

A Material Handling Blast from the Past

Huge Changes from Then to Now!

(Click on the pictures below to expand them)

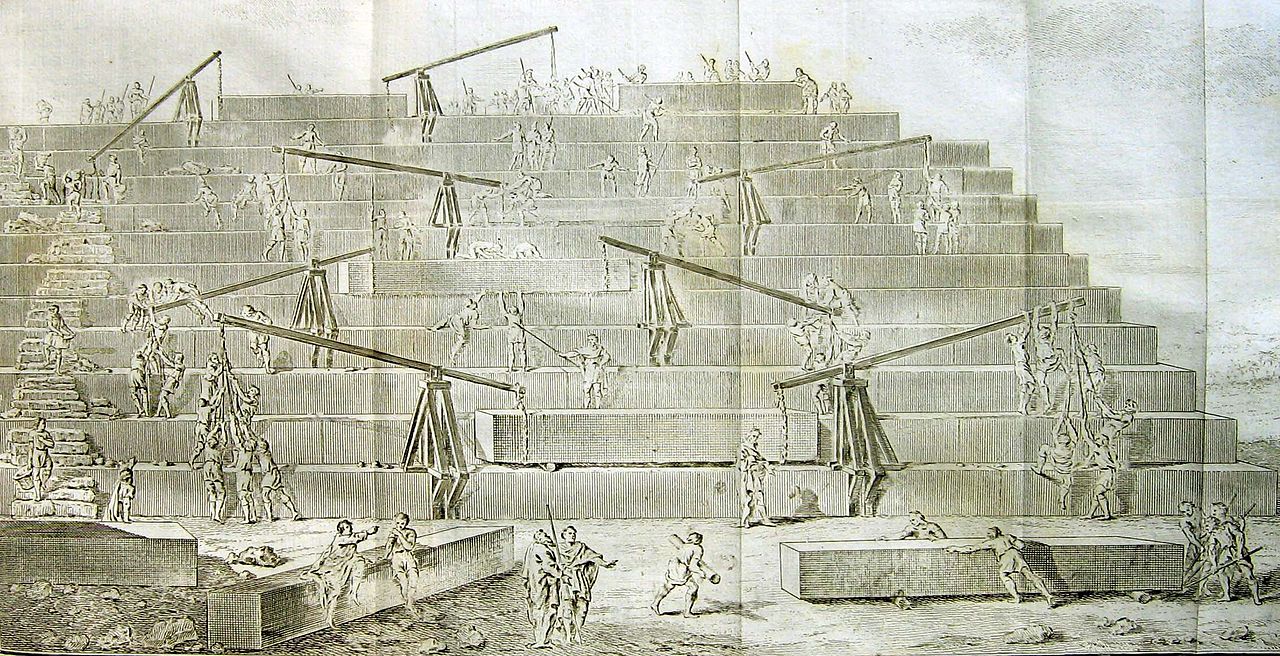

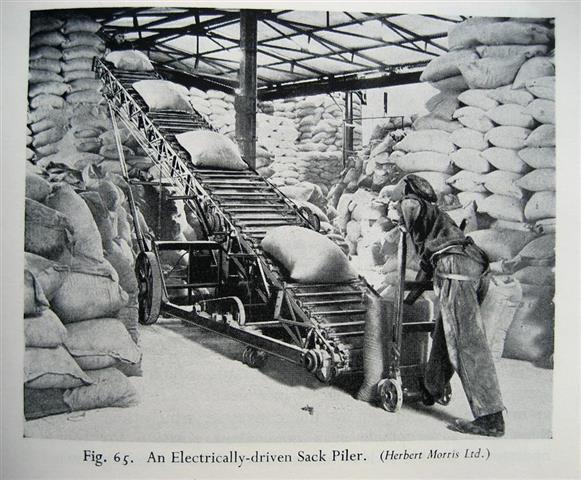

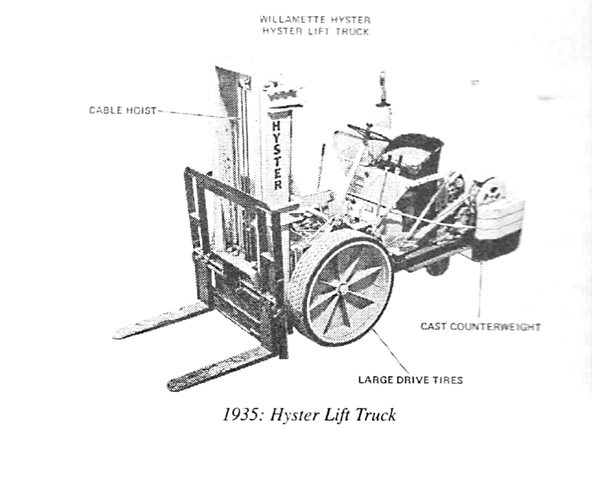

Moving loads and handling materials have been a part of human history from the beginning of time. Since before the building of the pyramids over 4,500 years ago, these tasks were carried out mostly by sweat, blood and brute force, utilizing simple mechanisms to aid them. Beasts of burden down through the ages also hauled and carried goods. But things have been changing rapidly over the past 150 years especially. Over the years, material handling has become an industry in itself. We’ve evolved from the use of ramps, levers, pulleys, and draft animals to utilizing a combination of non-mechanical and complex high-tech systems in material handling.

Over the centuries the methods have changed radically in every sector of industry, commerce and agriculture. But the greatest advancements in the movement, storage, control, and protection of materials has seen in the past 20 years or so. Automation and industrial robotics now play an increasing role in the workplace.

And while the world seems to be shrinking in view of the increasing complexity of the global market, the hardworking business person appreciates individual care.

We would love to be a part of increasing the

safety and organization

of your facility.

Give us a Call!

Sampson Industrial has gained

valuable knowledge through many years of experience! We are available for consultation and will be happy to advise you on solutions that may work best for your individual needs. Our cost-effective Redirack

industrial pallet racking and heavy-duty shelving will increase your inventory storage capacity, control and accessibility.

Give us a call! We would love to

be a part of increasing the safety and organization of your facility.

And if there is something that you would like to add to what we've shared here that will benefit other readers, please share it in the form below. It's great when we can all learn from one another.

Share Your Industrial Pallet Racking, Material Handling and Warehouse Knowledge

Do you have experience in the warehouse? Have you learned valuable Industrial Pallet Racking tips, tricks, and knowledge that you can share with others? Share it here, and include photos if you'd like!

We Created This Website

With SBI!

If we can do it, you can too!

.

Translate this page! Traduire cette page!

¡Traduzca esta pagina!

Übersetze diese Seite!

Search our Site