Adjustable Pallet Racking Components

The Redirack brand of adjustable pallet racking systems (also Redi-Rack or sometimes Ready Rack) is made up of several industrial pallet racking components that, when placed together, comprise your solid steel racking and shelving.

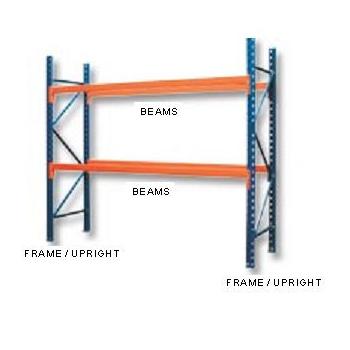

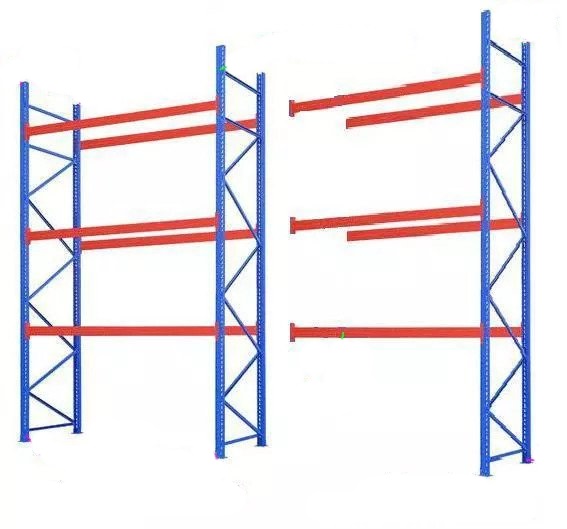

Uprights or End Frames

The uprights (or end frames) determine the height and depth of your adjustable pallet racking units. They are the lateral structures that hold the beams (or cross bars) in place. We have a wide variety of Redirack uprights of varying height and depth. Heights can range from workbench size to over 25 feet tall. The depths of the upright end frames also vary, accommodating a multitude of uses. A common width used in the warehouses is 42" which fits a standard 40”x 48” skid or pallet. Racks 18" to 24" wide is a common size for an automotive shop or garage on which tires fit nicely depending on their sizes. The Redirack adjustable pallet racking upright frames are fully welded.

In addition to the standard depths of industrial pallet racking, we also provide a variety of depths in the RediRack adjustable pallet racking.

For example, racks 18" to 24" deep is a common size for an automotive shop or garage on which tires fit nicely, depending on the tire sizes.

This photograph shows how one of our clients, Glengarry Tire, is utilizing the used Redirack industrial racking which they purchased from Sampson Industrial. It holds the tires nicely and helps to keep their operation organized.

The size of racking that they are using in this photo is 18 inches deep which stores vehicle tires perfectly.

Being a rural business, they also purchased some deeper 42 inch racking as well, which they use for storing tractor tires.

Beams or Cross Bars

Beams (or cross bars) are attached to the upright frames, spanning horizontally between uprights. They form the shelving levels (or tiers) of the RediRack adjustable pallet racking system.

There are varying sizes and lengths of beams, as well as different types of beams such as box beams and step beams. The larger the beam, the stronger the support to accommodate different weight loads. It is very important to know the weight that each level will be bearing when purchasing your Redirack racking. If you need to consult with us about your requirements, please feel free to do so. If you have any questions, we're always glad to take the necessary time to advise regarding racking safety of your facility, which is very important to us.

Redirack has uniquely shaped connectors at the end of each beam which differ from other brands of industrial pallet racking. Redirack beams have three hooks on the side and three punch-outs on the front which give the beam double anchoring stability and strength when connected to the upright frame.

There are two main types of Redirack beams: box beams and step beams. Box beams are stronger and able to take a heavier load than the step beams. Step beams have a step on the inside of the beam enabling the clip-in safety bar to fit on the inside so the top of the beam is flush with the safety bar.

Safety Bars

To complete the shelf at each level, one of two choices is required to span between the beams of your adjustable pallet racking: safety bars or wire mesh decking.

When utilized for pallet storage, safety bars work well enough. They add stability to the structure and keep the loaded pallets from falling through. They are superior in many ways to wooden decking. Decking made of wood products such as plywood or partial board are not only a fire hazard, but they block visibility, collect dust, and do not last as long.

Although the use of safety bars is definitely recommended over wooden decking, being superior to wood in many ways, the wire mesh decking is the standard when it comes to the different options for decking of your adjustable pallet racking structure.

.

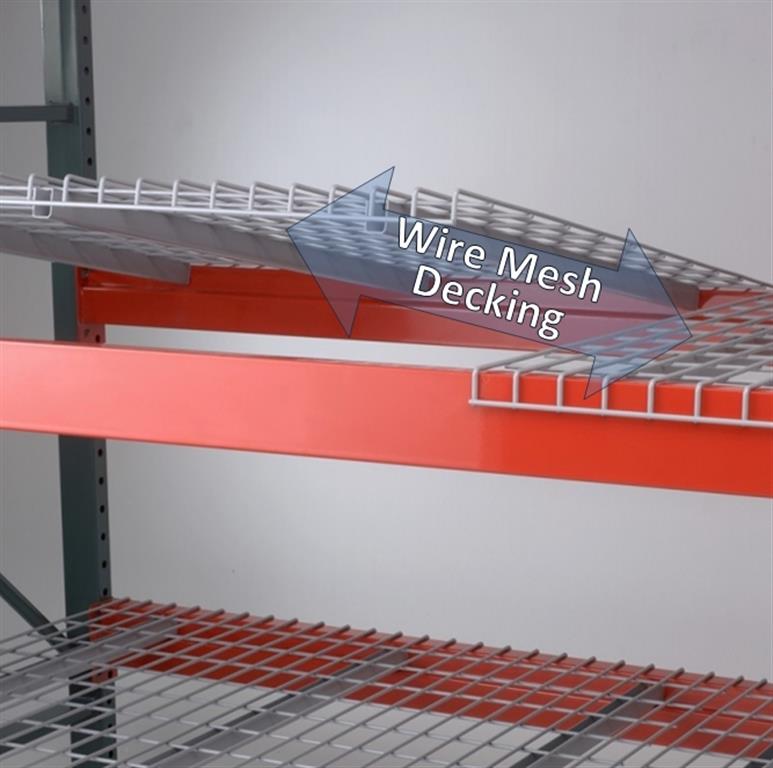

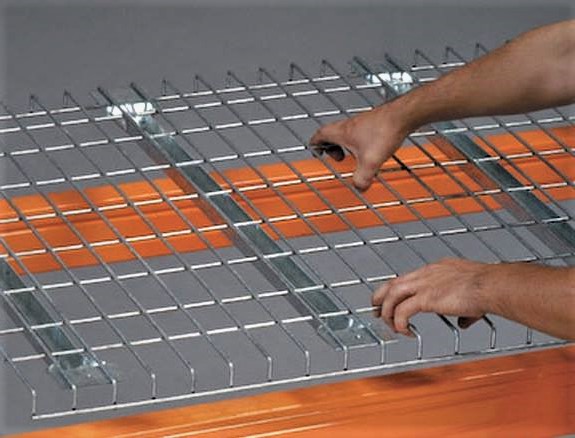

Wire Mesh Decking

Wire Mesh Decking is the best choice for spanning between your horizontal beams, allowing for large and smaller stock alike to be placed on the levels, as well as enforcing the security of the racking bay.

Wire Mesh Decking is the best choice for spanning between your horizontal beams, allowing for large and smaller stock alike to be placed on the levels, as well as enforcing the security of the racking bay.Wire decking is a very popular choice with our clients. It is the safest as well. Wire mesh decking also spanning between the beams. It serves as a strong, see-through “shelf” for storing your materials and products. Wire mesh decking is used for a wide variety of applications. It is definitely recommended for replacing plywood, press-board, and other wood decking which collected dust and debris and was a fire hazard. Wire mesh decking does not fuel a fire as wood products to, but it also allows water to pass through them in the event of a fire. Wire decking meets safety and fire code requirements, is very stable, much stronger, versatile, and durable.

Since safety is always the number one priority in any warehouse environment, we would recommend wire mesh decking as the first choice to finish off your racking.

They add stability to the structure of your industrial pallet racking units by equally distributing weight across its beams. This heavy duty wire mesh decking is ideal for use in many applications, not only for placing fully loaded pallets on them, but for open pallets, loose items, and irregular shaped or smaller sized stock as well.

The built-in safety bars that are part of the wire mesh decking is an excellent option for storing loose items. It very simple to install, free of maintenance care, not susceptible to damage, and is cost-effective, and they not only add to the safety of the employees but also of the products themselves.

When you install wire mesh decking as part of your adjustable pallet racking structure, you’re adding tried and proven surety against products slipping through the racking system and causing employee injury, damage to your stock, as well as to your material handling equipment. In addition to their vitally important safety value, wire mesh decks also make order filling easier, enabling employees to see products on upper tiers more clearly.

For valuable information regarding Seismic Behavior of Steel Storage Pallet Racking Systems, we recommend this book by Carlo Andrea Castiglioni, PhD, who is Full Professor of Structural Design at Politecnico di Milano, Milan, Italy.

In this valuable resource, Professor Castiglioni presents the main outcomes of the first European research project on the seismic behavior of adjustable steel storage pallet racking systems.

If you are located in an area that is affected by earth quakes, this knowledge-packed, highly informative book is a must read!

Adjustable Pallet Racking Corner Protectors

Pallet racking corner protectors are designed to protect the bottom part of the upright frame from damage that can be caused by forklifts or other mobile equipment.

It is nearly impossible to eliminate accidents in the workplace, especially when using fork lifts in a busy warehouse. However, pallet racking corner protectors provide a cost-effective way to reduce potentially expensive damage to your pallet racking uprights.

Row Spacers

Row spacers (also called Run Spacers) are attached to pallet racking units when they are arranged in back-to-back rows. The spacers are mounted between adjacent columns to ensure that the rows are kept straight and to give the pallet racks even more strength and stability, maintaining a fixed safety clearance between double sided rows (or runs) of racking.

We carry all these pallet racking components and more!

Contact Us for a consultation or quote today!

Share Your Industrial Pallet Racking, Material Handling and Warehouse Knowledge

Do you have experience in the warehouse? Have you learned valuable Industrial Pallet Racking tips, tricks, and knowledge that you can share with others? Share it here, and include photos if you'd like!

Shop For Material Handling Products

Shop For Protective Safety Workwear

Shop for Industrial Protective Safety Wear - Canada

We Created This Website

With SBI!

If we can do it, you can too!

.

Translate this page! Traduire cette page!

¡Traduzca esta pagina!

Übersetze diese Seite!

Search our Site